F. Size Set Sample

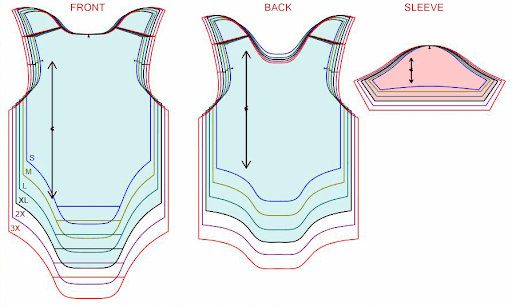

A size set sample is a collection of garments in different sizes. This sample is used to check the fit across various sizes, ensuring consistency and accuracy in sizing.

G. Pre-Production Sample

A pre-production sample is created before the mass production of a garment. It is the last chance to make adjustments before the full production run begins.

H. Top of Production Sample

The top of production (TOP) sample is the first completed garment from the manufacturing process. It is reviewed to ensure that the entire production line is aligned with the design and quality standards.

I. Shipment Sample

The shipment sample is created for international shipping, ensuring the final product meets the specifications and standards required for the market.

J. Showroom Sample

Showroom samples are produced for display at trade shows, fashion events, or showrooms. These samples are typically the final, polished versions of the product, used to attract buyers and partners.

K. Line Sample

Line samples represent a designer’s entire collection and are used in showroom settings or fashion shows. These samples help buyers get an overall sense of the collection’s design, style, and color palette.

L. Swatch Sample

Swatch samples are small pieces of fabric or materials used to showcase textures, colors, and patterns. They allow designers to select the right materials for production.

M. Virtual Sample

Virtual samples are digital representations of garments, used in the design process before physical samples are produced. This innovation helps reduce the need for physical samples and speeds up the development process.

N. Lab Dip Sample

Lab dip samples are fabric swatches dyed in specific colors for approval. These samples are used to ensure that the correct shades of dye are achieved before mass production begins.

Advantages of Utilizing Various Apparel Samples

The use of different types of apparel samples offers a range of advantages that benefit the entire production chain, from design to retail.

A. Ensuring the Quality and Accuracy of the Final Product

Samples allow designers and manufacturers to detect and address issues early on, ensuring the final product meets both the design vision and the quality standards required for the market.

B. Streamlining the Production Process

Samples help streamline the production process by identifying potential issues in design, fit, and construction before full-scale production begins, preventing costly mistakes and delays.

C. Facilitating Communication Between Designers and Manufacturers

Apparel samples act as a tangible communication tool between designers and manufacturers, enabling both parties to align their expectations and avoid misunderstandings during the production process.

Challenges in the Development and Utilization of Apparel Samples

While apparel samples offer numerous benefits, they also come with several challenges that fashion brands must navigate.

Cost Implications

Creating multiple types of samples can be costly, especially when it involves high-end materials and intricate designs. However, the investment is often justified by the benefits of reducing errors and enhancing product quality.

Time Constraints

The process of creating apparel samples can be time-consuming, especially when multiple iterations are needed to perfect the design. Tight production schedules may exacerbate these delays.

Environmental Impact

The production of physical apparel samples generates waste, which can have a significant environmental impact. This includes the use of resources for materials and the transportation of samples globally.

The Future of Apparel Samples in 2025

As we approach 2025, the role of apparel samples in fashion production is poised to evolve with emerging trends and technologies.

Technological Advancements in Sample Production

The future of apparel samples will likely see an increase in the use of 3D technology, digital prototyping, and automated manufacturing processes, allowing for faster, more accurate sample creation with less material waste.

Shift Towards Sustainable and Eco-Friendly Samples

Sustainability is becoming a top priority for many fashion brands, and the future will see more eco-friendly practices in the sampling process. This could include the use of recycled fabrics, biodegradable materials, and less wasteful production methods.

Increased Focus on Virtual Samples and Digital Prototyping

Virtual samples will become more prevalent, reducing the need for physical samples. This digital approach allows designers to experiment with designs and make changes quickly, thus speeding up the overall production timeline.

Commonly Asked Questions About Apparel Samples

1. What is the purpose of a fit sample?

A fit sample is used to check the garment’s fit and ensure it meets sizing specifications. It helps identify any design or sizing adjustments needed before production begins.

2. How can virtual samples enhance the design process?

Virtual samples allow designers to visualize and adjust garments in a digital format, significantly reducing the need for physical samples and speeding up the decision-making process.

3. What impact do samples have on overall production costs?

Although the creation of apparel samples incurs costs, it can ultimately reduce production costs by preventing errors, ensuring quality, and improving the efficiency of the manufacturing process.

Conclusion

As the fashion industry continues to evolve, the importance of apparel samples cannot be overstated. These samples serve as crucial tools for ensuring quality, accuracy, and efficiency in the apparel production process. In 2025, we can expect to see further advancements in sampling technology, as well as a greater emphasis on sustainability and digital solutions. By understanding the various types of apparel samples and the role they play in the production chain, fashion brands can stay ahead of trends, optimize their processes, and deliver high-quality products to market faster and more cost-effectively. Whether through physical or virtual samples, the future of apparel production promises to be more innovative, sustainable, and consumer-focused. Contact Mj-clothing for more professional information.