Clothing Sample Maker: A Key Role in Creating a Perfect Clothing Collection (Analysis of 10 Core Values)

Abstract

In the clothing production process, sample making is the key bridge between design and mass production. Clothing Sample Maker A professional clothing sample maker can help brands save up to 30% of development costs and shorten product launch time by 50%. This article will deeply analyze the 10 core values of sample makers, including professional skills, cost control, quality control, communication efficiency, supply chain integration and other key dimensions, and attach actual case analysis to help clothing brand owners fully understand the decisive impact of this important role on product development.

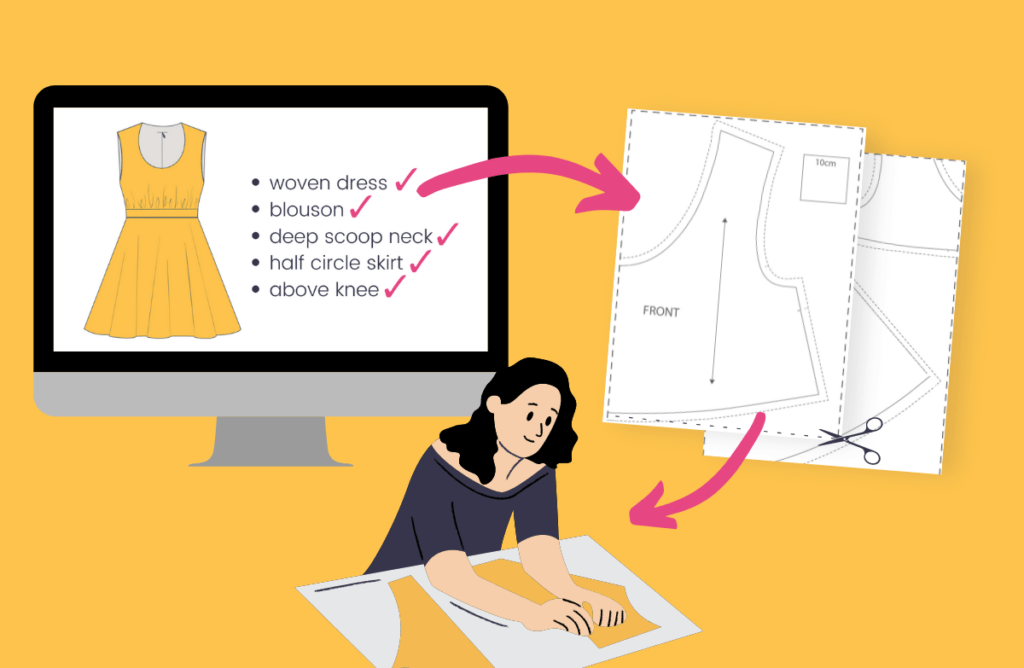

1. The core functions of sample makers

Clothing Sample Maker Argument: Sample makers are the professional bridge between design and mass production

- Argument:

- Responsible for converting design drawings into physical samples (average 3-5 modifications per model)

- Must be proficient in fabric characteristics, sewing techniques and pattern adjustments (e.g. different processing methods for knitting and woven fabrics)

- Case: An emerging brand shortened its development cycle from 8 weeks to 3 weeks through professional sample makers

2. The value of professional sample rooms

Clothing Sample Maker Argument: Professional sample rooms can improve development efficiency by 50%

- Argument:

- Equipped with professional equipment (such as 3D body scanners, industrial sewing machines)

- Establish a standardized sample management system (classified and stored by series/season)

- Data: Brands with professional sample rooms have a 65% increase in the first sample pass rate

3. The importance of technical package files

Argument: A complete technical package can reduce 80% of communication errors

- Argument:

- Contents that must be included: process sheet, size table, fabric sample, auxiliary material list

- Excellent case: ZARA’s technical package includes 360-degree renderings + video instructions

- Data: Brands using standardized technical packages have an average of 3 fewer sample modifications

4. Three stages of sample production

Argument: Phased production can effectively control development risks

- Argument:

- Prototype sample: Verify design feasibility (success rate of about 60%)

- Sales sample: Confirm market response (collect buyer feedback)

- Pre-production sample: Determine mass production standards (error must be <0.5cm)

5. The key to cost control

Argument: Professional samplers can save 30% of development costs

- Argument:

- Reasonable selection of alternative fabrics (without affecting the effect)

- Optimize the process route (such as simplifying unnecessary decoration processes)

- Case: A brand reduced the development cost of a single item from $2000 to $1400 through sample optimization

6. Quality control system

Argument: The cost of discovering problems in the sample stage is 1/10 of that after mass production

- Argument:

- Tests that must be conducted: color fastness, shrinkage, seam strength

- Professional equipment: Martindale abrasion tester, tear strength tester

- Data: Strict sample quality inspection can reduce the defective rate of mass production by 40%

7. Supply chain synergy advantage

Argument: Samplers can optimize overall supply chain efficiency

- Argument:

- Confirm the supply cycle of surface and auxiliary materials in advance (avoid mass production delays)

- Establish a standardized process library (shorten the running-in period of new factories)

- Case: A cross-border e-commerce company increased the supply chain response speed by 2 times through samplers

8. Pattern optimization value

Argument: Professional pattern adjustment can increase marketability by 30%

- Argument:

- Adjustment based on body shape data of different markets (such as Asian vs. European and American patterns)

- Use 3D simulation technology to reduce the number of physical proofing times

- Data: The return rate of professionally adjusted styles is reduced by 25%

9. Intellectual property protection

Argument: The sample stage is the key period for IP protection

- Argument:

- NDA confidentiality agreement must be signed (covering design details)

- Disclose technical information in stages (avoid leakage of complete solutions)

- Case: A designer brand’s imitation products were launched early due to sample leakage

10. Sustainable sample development

Argument: Green samples have become an industry trend

- Argument:

- Use digital samples to replace some physical samples (saving 50% of materials)

- Establish a sample recycling system (fabric utilization rate increased to 85%)

- Data: Brands that adopt sustainable sample solutions have an average ESG score increase of 20%

Summary: 5 golden rules for selecting sample makers

- Professional qualifications: Check past portfolios and technical team configuration

- Equipment level: Confirm whether professional proofing equipment is available

- Supply chain resources: Evaluate the ability of the surface and auxiliary material procurement channels

- Communication efficiency: Test the technical understanding ability and response speed

- Cost control: Compare the cost-effective solutions of different quotations

Action suggestions:

- For start-up brands: It is recommended to choose suppliers that provide “sample + small batch” integrated services

- Mature brands: Establish a dedicated sample team, and the cost is better when the annual development volume exceeds 200 models

- Cross-border e-commerce: Focus on the quick response ability of the sampler (complete the sample within 7 days)

Industry trends: 3D digital sample technology is developing rapidly. It is expected that 30% of physical samples will be replaced by digital solutions in the next three years, but high-end fashion will still maintain the physical sample making process. It is recommended that brands choose appropriate sample development strategies based on product positioning.